Concrete Driveway Expansion Joints in Cape Coral, Where They Should Go and Why They Crack When They Don’t

A concrete driveway looks solid and permanent, so it’s frustrating when hairline cracks show up a few months after a pour. In Cape Coral, that surprise is common, not because the concrete was “bad,” but because concrete naturally shrinks as it cures and it moves with heat and moisture.

That’s the real job of driveway expansion joints and control joints: they don’t stop cracking, they choose where it happens . When joints are missing, too far apart, or cut too shallow, the slab still relieves stress, just in the most random and visible place.

If you’re a homeowner or property manager planning a new driveway or widening an existing one, this guide covers where joints should go, why they matter in Southwest Florida, and what to ask a concrete company before the truck shows up.

Why driveway expansion joints matter in Cape Coral

Cape Coral driveways take a beating from sun, sudden rain, and sandy soils. Concrete expands when it heats up and shrinks as it cools. It also shrinks as it dries and hardens. Add heavy vehicles and occasional soft subgrade spots, and the slab is always looking for a weak point to release tension.

A joint is a planned “weak point” that looks clean and intentional. Without it, cracks often run corner-to-corner like lightning, especially near re-entrant corners (think: the inside corner where a driveway meets a walkway).

Local rules and best practices point you in the same direction. The current code in use is the 2023 Florida Building Code (8th Edition). It references industry standards for concrete construction, which is why contractors often cite ACI guidance. If you want to see the concrete chapter that Florida adopts for many structural concrete provisions, read Florida Building Code Chapter 19 (Concrete).

For joint types and why they exist, ACI’s classic report is a helpful deep read, even for non-engineers: ACI 224.3R, Joints in Concrete Construction (PDF).

And remember, driveway work rarely happens alone. Driveway edges tie into landscaping , walkway paths, irrigation lines, and sometimes pavers. Coordinating those trades matters as much as the concrete itself. (If you’re planning the full exterior, this overview of Cape Coral landscaping and paver services helps connect the dots.)

Isolation joints vs control joints (the simple way to think about it)

Homeowners hear “expansion joint” used as a catch-all, but there are two joint types that matter most for residential driveways.

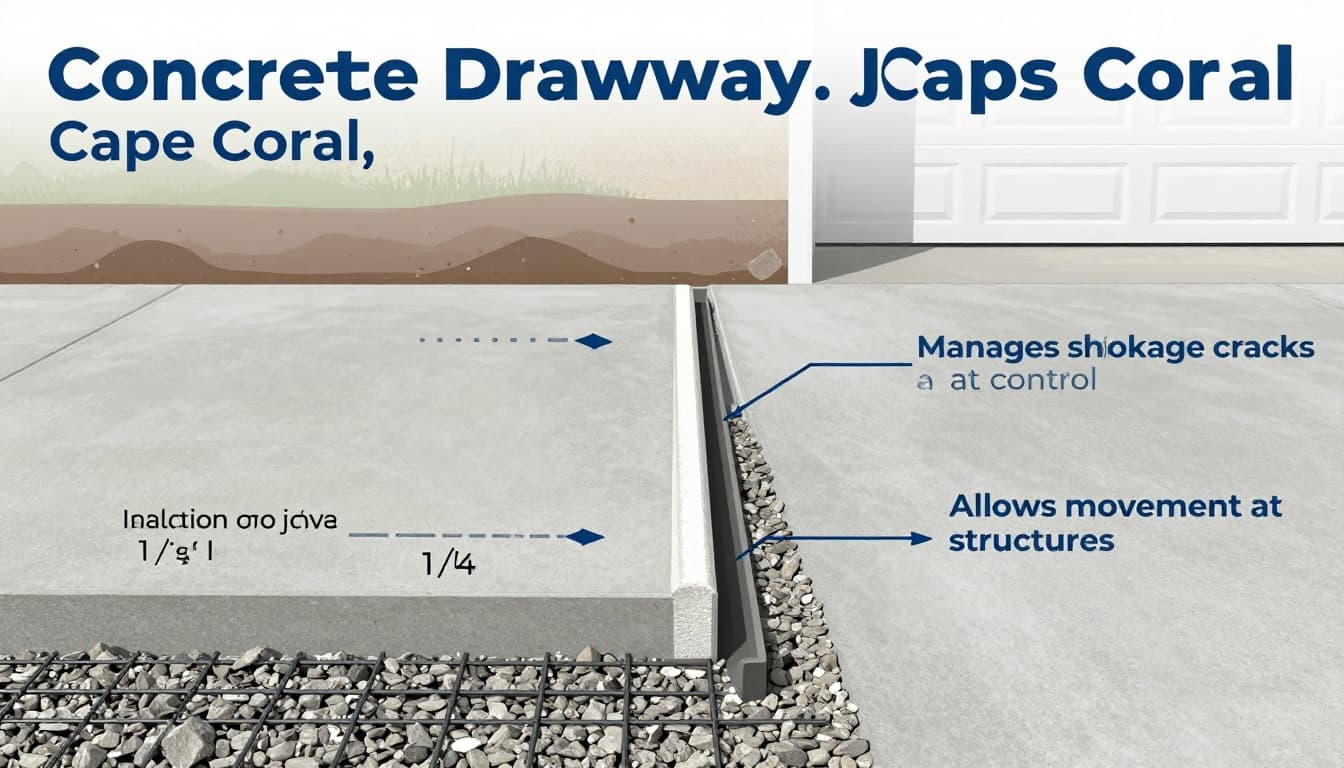

Isolation joint (often called an expansion joint) : Think of this like the foam bumper between two shopping carts. It separates the driveway slab from something that shouldn’t get pushed or pulled by the slab, like a garage slab, stem wall, sidewalk, or an existing driveway pour. It’s typically a full-depth separator (foam, fiberboard, rubberized material) and it’s often sealed at the top.

Control joint (also called a contraction joint) : Think of this like a zipper line on a bag of chips. It tells the slab, “If you’re going to tear, tear right here.” It’s usually a saw cut or tooled groove that’s deep enough to create a weak plane so the concrete cracks underneath that line instead of somewhere else.

Rules of thumb that work well for Cape Coral driveways (typical two-car driveway, 4-inch slab ):

- Control joint spacing: commonly 8 to 12 feet , with many contractors aiming closer to 8 to 10 feet for 4-inch residential work.

- Keep panels square: long skinny rectangles crack more often than near-squares. A good target is panels where the long side is no more than about 1.5 times the short side.

- Depth matters: control joints are often cut to about 1/4 of slab thickness , so about 1 inch deep for a 4-inch driveway.

Where driveway expansion joints should go on a Cape Coral driveway

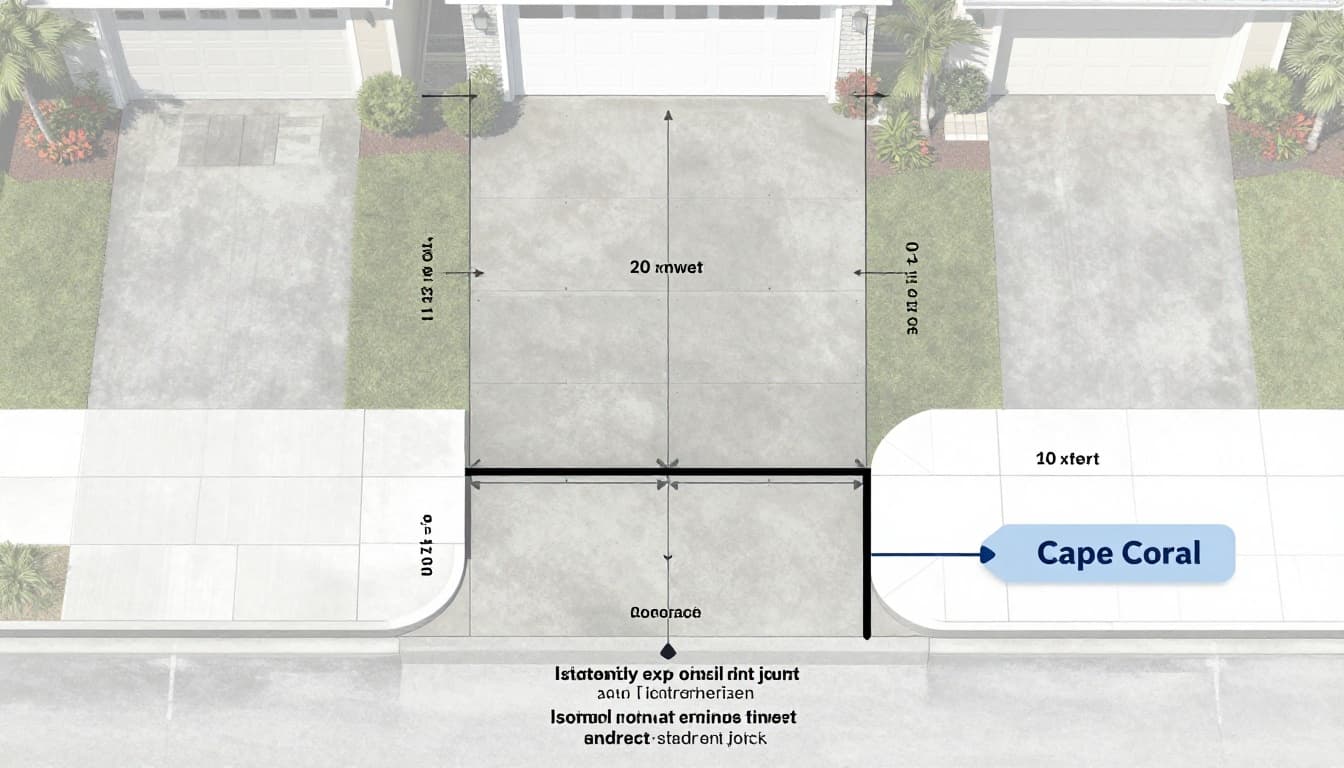

Plan view showing typical isolation joint locations and a clean control-joint layout for a two-car driveway, created with AI.

Plan view showing typical isolation joint locations and a clean control-joint layout for a two-car driveway, created with AI.

If you only remember one idea, make it this: put isolation joints where the driveway meets something that won’t move the same way, then lay out control joints so the remaining panels are neat, square-ish, and consistent.

Here’s practical placement guidance for a common Cape Coral setup (about 20 feet wide by 30 feet long, 4-inch slab), including driveway widening projects:

- At the garage slab/house interface: Use an isolation joint between the driveway and the garage slab or stem wall. This keeps driveway movement from pushing into the structure.

- At the sidewalk/approach: Where your driveway meets the city sidewalk or apron, an isolation joint helps prevent one slab from “jacking” the other during movement.

- Where new concrete meets old concrete: If you’re widening an existing driveway, separate the new pour from the old with an isolation joint unless a pro has designed a dowel system for that condition. Tying pours together without planning often leads to a crack right along the seam anyway, just uglier.

- Control joints to break up the field: For a 20-foot-wide driveway, many layouts use a center control joint lengthwise, then cross joints every 8 to 10 feet. That gives you panels close to 10 by 10 feet, which behave well.

Also think about what borders the driveway. If you’re pairing concrete with pavers, plan for cleaning and sealing so the joint stays crisp. Routine paver cleaning keeps sand and debris from washing into open joints along the edge. If your design includes artifical turf strips between hard surfaces, edge restraint and drainage planning become even more important because trapped water makes joint and base problems worse.

For property managers juggling multiple outdoor upgrades, it helps when one crew can coordinate. A Concrete contractor in Cape Coral that also understands grading and drainage can prevent the “perfect slab on a bad base” problem.

Why they crack when they don’t (and how to protect the joint)

Cross-section showing how isolation joints allow movement and control joints guide cracking, created with AI.

Cross-section showing how isolation joints allow movement and control joints guide cracking, created with AI.

Concrete cracks when stress builds faster than the slab can handle, and joints are the release valves. The most common reasons Cape Coral driveways crack “randomly” are simple:

Joints are too far apart , so the slab makes its own crack. Joints are too shallow , so they don’t create a true weak line. Joints are placed without a plan , leaving odd-shaped panels and re-entrant corners that crack diagonally. Sometimes the base isn’t compacted well, so one area settles and the slab bends.

One caution before you “just cut a joint” into an existing driveway: don’t assume what’s inside the concrete. Some slabs are reinforced in ways you can’t see. If the driveway is post-tensioned (more common in some regions and applications) or simply unknown, uncontrolled cutting can be risky. When in doubt, have a pro evaluate before saw cutting.

Finally, don’t ignore joint sealing. In Cape Coral rain, unsealed joints can funnel water into the base, washing out support over time. A common approach is cleaning the joint, installing backer rod, then applying a flexible sealant that can handle movement. Sealing also helps keep weeds and ants from turning joints into a mess, especially near beds and landscaping borders. If you’re updating the yard at the same time, combining driveway work with sod and artificial turf installation in Cape Coral can help you regrade edges cleanly and keep runoff away from the slab.

What to ask your contractor before the pour

- “Where will the isolation joints go?” Listen for: garage interface, sidewalk/approach, and any place new concrete meets existing slabs.

- “What control joint spacing are you using for a 4-inch slab?” A clear answer is usually in the 8 to 12 foot range, with a layout that keeps panels close to square.

- “How deep will the saw cuts be, and when will you cut them?” Depth and timing both matter for clean crack control.

- “Are you sealing joints, or should I schedule that?” If sealing isn’t included, ask what product they recommend and when it should be applied.

- “How will you prep and compact the base?” Great joints won’t save a slab poured over soft spots.

Cracks aren’t a moral failure of concrete, they’re part of how it behaves. With smart driveway expansion joints , proper control joints, and good base prep, you get cracks that stay quiet, straight, and far less noticeable.